This is a purification equipment consisting of 4 low-altitude Commercial Electrostatic Precipitator Air Purifiers. It can handle 12,000m³ of kitchen fumes per hour (estimated to be the smoke exhaust volume of 4 gas stoves). It is suitable for backyard barbecues, food trucks, and Asian restaurants. It makes the kitchen fume purification efficiency reach 95%, meets the national fume emission standards, and gives chefs and diners a fresh dining environment.

Model:LF-JDW-DB-12

Certificate:CCC / ISO / CEP

Service:Customized OEM / ODM

It uses the principle of electrostatic adsorption to remove oil smoke and impurities generated during the cooking process.

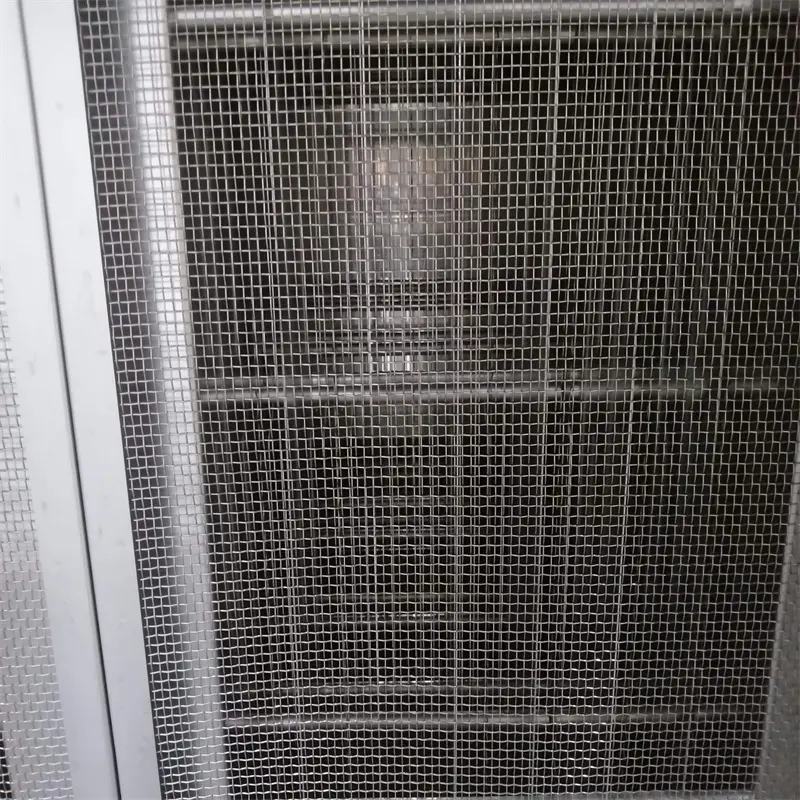

When the oil fume enters the ionization field, it will be separated by the positive and negative electrodes in the high-voltage electric field, and then the charged grease particles and oil mist molecules will be adsorbed to the oppositely charged electrode plate.

This process will effectively remove grease, particulate matter and other impurities in the oil fume, allowing the discharged oil fume to achieve a purification rate of 95%.

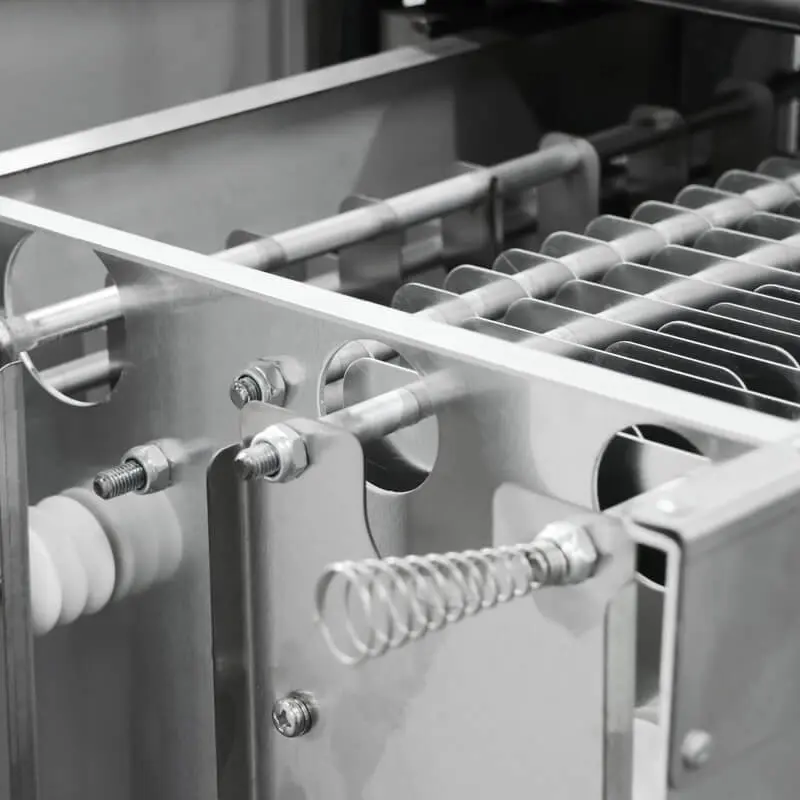

The ionization field is made of aviation-grade aluminum alloy material. This material has good electrical conductivity, high adsorption efficiency and good corrosion resistance.

It provides stable performance in high humidity, high temperature and high-intensity electric field environments.

A high-strength aluminum plate frame and dry-pressed alumina insulating ceramics are added to the edge of the electric field to provide longer creepage insulation distance and higher safety.

Its separation force is electrostatic force, which can directly act on oil fume particles instead of in the air flow, which can improve the effective use of electrostatic force.

With less power consumption, the oil fume purification efficiency reaches 95%. It handles more than 12,000m³ of kitchen fume per hour (estimated as the fume production of 4 gas burners).

It adopts an intelligent high-voltage constant power supply that can adjust the intensity of the ionization field in real time.

It is equipped with a real-time display ammeter, which can monitor the current of the ionization field, the equipment operating status and the operation indicator light in real time.

It uses dual-frequency control technology with non-inductive pulses instead of the single-frequency control system commonly used in the industry, which enables the equipment to maintain a 95% oil fume purification rate after long-term operation.